Our Polyurethane Selection Guide will help you discover the large range of polyurethane systems we supply, and figure out which product is best suited for you. Our Polyurethane products are broken down into 4 categories – Rigid, Flexible, Expanding Foam, and Water Clear. We explore each group and the features that differentiate the various systems, plus tips and tricks on getting the most from your polyurethane product. For the best results, please use a vacuum degasser with rigid and elastomer polyurethanes to remove air from your mixture.

Rigid Polyurethanes - Aromatic

Our Rigid Aromatic polyurethanes are the most common type of casting PU, as they are generally more economical, offer good physical properties, and come in both rigid and elastomeric formulations. However, Aromatic resins can have poor UV and chemical resistance. If colour stability and resistance to environmental oxidation are important, consider using our UV Additive.

| NAME | RATIO | POT-LIFE 100gm @25ºC | DE-MOULD | SHORE D | VISCOSITY | COLOUR | HDT @ 62psi | TENSILE STRENGTH (psi) | SHRINKAGE | FLEX MODULUS (psi) |

|---|---|---|---|---|---|---|---|---|---|---|

| EASYCAST | 100:100 PBV | 2-2.5 MINS | 15+ MINS | 65+2 | 60 cps | White | 65°C | 2,936 | 0.0041 | 93,112 |

| EASYCAST 120 | 100:100 PBV | 2-2.5 MINS | 15+ MINS | 65+2 | 120 cps | White | 71ºC | 5395 | 0.0169 | 133,765 |

| BQUEEN | 100:100 PBV | 2-2.5 MINS | 15+ MINS | 72+2 | 110 cps | Translucent Amber/Yellow | 56ºC | 4091 | 0.0154 | 97,532 |

| SUPERCAST | 100:100 PBW | 3 MINS | 30+ MINS | 70+2 | 200 cps | Beige/Tan | 80ºC | 3389 | 0.009 | 198,000 |

| PROCAST | 100:100 PBW | 5 MINS | 60+ MINS | 65+2 | 150 cps | Beige/Tan | 60ºC | 4450 | 0.0169 | 209,000 |

| TC808 | 100:100 PBW | 2-2.25 MINS | 30-60+ MINS | 78+2 | 200cps | White | 76ºC | 6,000 | 0.004 | 170,000 |

| TC808 JET BLACK | 100:100 PBW | 2-2.25 MINS | 30-60+ MINS | 78+2 | 200cps | Jet Black | 76ºC | 6,000 | 0.004 | 170,000 |

| TC890 | 100:100 PBW | 5 MINS | 1-2 HOURS | 80+2 | 725 cps | White | 90ºC | 7,600 | 0.004 | 250,000 |

| TC891 | 100:100 PBW | 12 MINS | 3-4 HOURS | 80+2 | 725 cps | White | 90ºC | 7,600 | 0.003 | 250,000 |

| TC892 | 100:100 PBW | 20 MINS | 5-6 HOURS | 80+2 | 725 cps | White | 90ºC | 7,600 | 0.005 | 250,000 |

| TC1630 | 100:100 PBW | 5-6 MINS | 60 MINS | 80+2 | 1,100 cps | Grey | 99ºC | N/A | 0.002 | N/A |

| MD60 | 100:50 PBW | 10-15 MINS | 2-3 HOURS | 60D | 2,200 cps | Amber | N/A | 4,700 | 0.005 | N/A |

*Please note the TC1630 is a filled polyurethane system.

**Please note the MD60 is a semi-rigid polyurethane for tough, high impact applications. This feels more like an elastomer compared to a plastic.

TC-808 Jet Black - Taxidermy Jaw

PROCAST - Climbing Holds

BQUEEN - Jewellery

FLEXIBLE POLYURETHANES

The following products can be broken down into three groups – The F-series, CF range and Flexicast systems.

- The F Series offers a Fast work time and Fast cure time, predominantly used for casting parts and have excellent physical properties.

- The CF range stands for Colour Flex, which may take on the true tones of a pigment if colour is an important feature. These are also primarily used for creating cast parts.

- And finally, the FLEXICAST range was designed for making high strength moulding rubbers for casting concrete, plasters and waxes. They may also be used to cast parts, but check the specs to see if an F series or CF product may be better suited.

| NAME | RATIO PBW | POT-LIFE 100gm @25ºC | DE-MOULD | SHORE A | VISCOSITY | COLOUR | TENSILE STRENGTH (PSI) | TEAR STRENGTH | ELONGATION (%) | SHRINKAGE |

|---|---|---|---|---|---|---|---|---|---|---|

| F-115 | 100:100 | 9-10 MINS | 3-5 HOURS | 15 | 1,200 cps | AMBER | 650 | 70 | 1,200 | 0.001 |

| F-125 | 100:100 | 6-7 MINS | 2-3 HOURS | 25 | 1,300 cps | AMBER | 680 | 80 | 1,000 | 0.001 |

| F-140 | 50:100 | 7-8 MINS | 3-4 HOURS | 40 | 1,100 cps | AMBER | 940 | 120 | 800 | 0.001 |

| F-150 | 50:100 | 6-7 MINS | 3-4 HOURS | 50 | 1,000 cps | AMBER | 1,020 | 125 | 650 | 0.0015 |

| F-160 | 50:100 | 5-6 MINS | 2-3 HOURS | 60 | 1,130 cps | AMBER | 1,260 | 150 | 625 | 0.0016 |

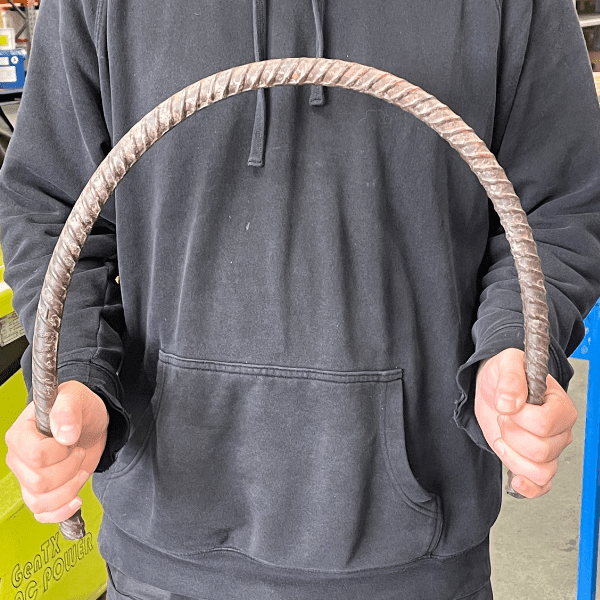

| F-170 | 50:100 | 5-6 MINS | 2-3 HOURS | 70 | 1,120 cps | AMBER | 1,803 | 245 | 1,147 | 0.0025 |

| F-180 | 100:50 | 8-9 MINS | 2-3 HOURS | 80 | 2,600 cps | AMBER | 3,720 | 385 | 650 | 0.001 |

| F-190 | 100:50 | 9-10 MINS | 2-3 HOURS | 90 | 3,450 cps | AMBER | 4,020 | 405 | 670 | 0.001 |

| CF-50AM | 50:100 | 12-14 MINS | 4-6 HOURS | 50 | 1,000 cps | MILKY WHITE | 550 | 40 | 250 | 0.005 |

| CF-60AM | 50:100 | 12-14 MINS | 4-5 HOURS | 60 | 650 cps | MILKY WHITE | 1,100 | 60 | 250 | 0.005 |

| CF-70AM | 50:100 | 12-14 MINS | 4-5 HOURS | 70 | 800 cps | MILKY WHITE | 1,550 | 100 | 300 | 0.005 |

| CF-80AM | 50:100 | 14-16 MINS | 3-4 HOURS | 80 | 650 cps | MILKY WHITE | 1,600 | 150 | 210 | 0.005 |

| CF-90AM | 50:100 | 12-14 MINS | 3-4 HOURS | 90 | 1,000 cps | MILKY WHITE | 2,500 | 180 | 250 | 0.006 |

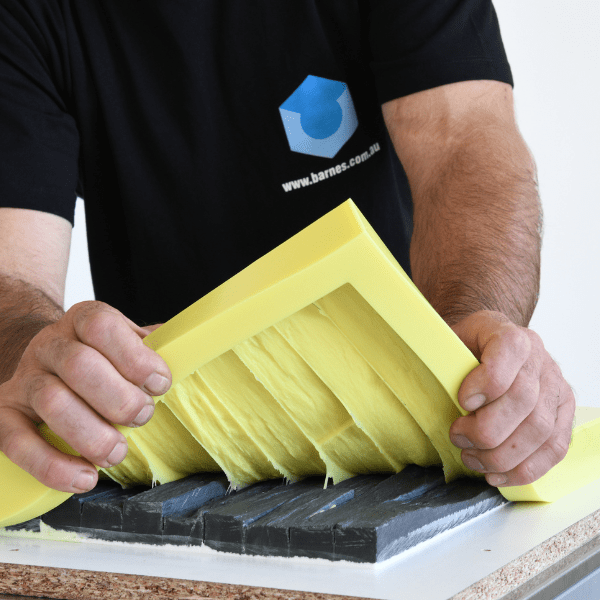

| FLEXICAST 20 | 50:100 | 20 MINS | 16 HOURS | 20 | 800 cps | YELLOW | 217 | N/A | 1,060 | N/A |

| FLEXICAST 45 | 100:100 | 30 MINS | 16 HOURS | 45 | 2,000 cps | YELLOW | 408 | N/A | 1,135 | N/A |

| FLEXICAST 65 | 100:100 | 35 MINS | 16 HOURS | 65 | 3,000 cps | TRANSLUCENT YELLOW | 520 | N/A | 550 | N/A |

FLEXICAST 20 - Mould

F-180 Rebar

COMING SOON

Expanding Foams

The foams may be easily navigated by name and number. The S is for Soft, and the R is for Rigid. The number indicates density, so the lower the number the lighter the foam, and the greater the expansion. Please use a wax based release agent like MACWAX or Challenge 95 with the foams, and AVOID silicone based release agents. Read the TDS for further information.

| NAME | DENSITY KG/M3 | WORK TIME 100gm @25ºC | TACK FREE TIME | RATIO PBW | EXPANSION RATE | FOAM TYPE | COLOUR |

|---|---|---|---|---|---|---|---|

| S-FOAM 50 | 50 | 8-12 SECONDS | 30-60 MINS | 100:45 | 20X | HI-RESILIENCE | CREAM |

| S-FOAM 65 | 64 | 15-20 SECONDS | 20-30 MINS | 75:100 | 7-8X | SELF-SKINNING | OFF-WHITE |

| S-FOAM 128 | 128 | 20-25 SECONDS | 30 MINS | 50:100 | 15-16X | SELF-SKINNING | OFF-WHITE |

| R-FOAM 33 | 33 | 20-25 SECONDS | 230 SECONDS | 100:100 | 30-31x | GENERAL PURPOSE | CREAM |

| R-FOAM 100 | 96 | 20 SECONDS | 3.5-4 MINS | 100:100 | 10X | SELF-SKINNING | CREAM |

| R-FOAM 200 | 190 | 20-25 SECONDS | 105 SECONDS | 100:100 | 5X | SELF-SKINNING | CREAM |

RFOAM 100 Free Rise Foam Cup

SFOAM 128 Foam Packaging Support for Machinery

COMING SOON

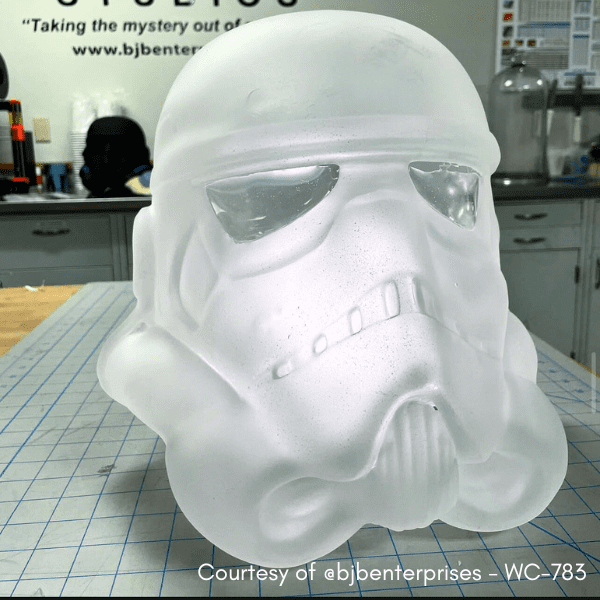

Water Clear Aliphatic Polyurethanes

Our Water Clear Polyurethanes are available in both rigid (Shore D) and flexible (Shore A) formulas. The Aliphatic polyurethanes can exhibit great UV & colour stability, and chemical resistance. Their downside is typically longer work times and de-mould times, low heat distortion, low tolerance to colder casting temperatures, and higher material costs.

| NAME | RATIO | POT LIFE 100gm @25ºC | DE-MOULD @25ºC | SHORE HARDNESS | VISCOSITY | COLOUR | SHRINKAGE (in/in) | TENSILE STRENGTH (psi) | TEAR STRENGTH (pli) | ELONGATION % | SPECIFIC GRAVITY |

|---|---|---|---|---|---|---|---|---|---|---|---|

| WC-540 | 50:100 PBW | 20 MINS | 8-12 HOURS | 45A | 910 cps | Colourless/Clear | 0.001 | 390 | 43 | 300 | 1.06 |

| WC-565 | 100:100 PBW | 15 MINS | 6-8 HOURS | 65A | 1,100 cps | Colourless/Clear | 0.004 | 753 | 59 | 200 | 1.02 |

| WC-595 | 100:90 PBW | 15 MINS | 6 HOURS | 95A | 900 cps | Colourless/Clear | 0.005 | 4,000 | 375 | 180 | 1.03 |

| WC-782 | 100:85 PBW | 15 MINS | 6-8 HOURS | 82D | 650 cps | Colourless/Clear | 0.003 | 6,650 | N/A | 65 | 1.05 |

| WC-783 | 100:90 PBW | 15 MINS | 6-8 HOURS | 82D | 650 cps | Colourless/Clear | 0.002 | 6,650 | N/A | 65 | 1.05 |

| WC-784 | 100:85 PBW | 6 MINS | 2-3 HOURS | 82D | 650 cps | Colourless/Clear | 0.004 | 6,650 | N/A | 65 | 1.05 |

| WC-786 | 100:96 PBW | 30 MINS | 6-8 HOURS | 80D | 600 cps | Colourless/Clear | 0.005 | 4,000 | N/A | 13+/-2 | 1.05 |

| Poly Optic 1411 | 100:100 PBV | 9 MINS | 30 MINS+ | 80D | 600 cps | Colourless/Clear | 0.0018 | 6,083 | N/A | 7 | 1.07 |

WC-783 Stormtrooper

WC-565 Taxidermy Jaw w/ Mandarine PSTF